Lancaster University engineers help discover the world’s biggest cave

The Organisation

Commendium Ltd specialises in telecommunications and digital solutions and have completed projects for a huge range of organisations, from some of the biggest names in the business to SMEs.

The Challenge

As a part of the company’s ongoing growth strategies, they sought to establish data collection methods for subterranean cavernous environments. This led to the company undertaking a series of surveys and collecting point cloud data from some of the world’s largest caves, using 3D scanning technology. The was approached with the point cloud data to use the expertise of the Engineering Graduate Academy to create 3D models.

Expertise Sought

- Use of 3D Scanning Technology

- Computer-Aided Design

- Selective Laser Sintering (SLS) modelling for analysis

The Solution

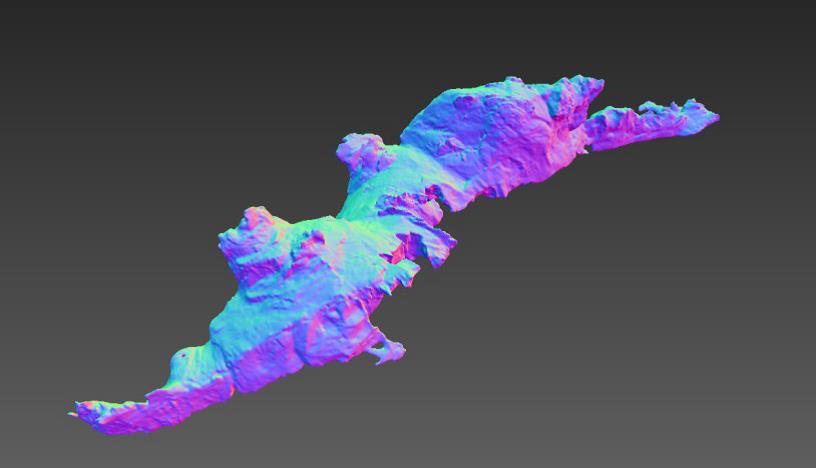

Scale models of all four caves were produced using SLS technology, splitting the models into multiple parts to allow for the study of the internal cavities. These models can be used to analyse the caves' structure and to create scale models, which could be used to help engineers and enthusiasts visualise the caves.

Cost

This work was part-financed by the European Regional Development Fund through the SusDRAM:EDA project, which provides SMEs in the northwest of England with mechanical engineering support.

Impact

Study of the 3D models confirmed that the Miao chamber in China is now the world record holder for the largest cave chamber at 10.78 Million m3, roughly 10% larger than the previous holder. This was reported in National Geographic, as well as several national papers.

Benefits to the company

- Established data collection methods for subterranean cavernous environments

- Devised an appropriate and cost-effective method for measuring volumes and printing 3D models

- Saved management time

Benefits to the university

- Increased knowledge of caves and cave mapping

Benefits to society

- The Miao chamber in China is now the world record holder for the largest cave chamber

- The models can be used to analyse the cave's structure and to create scale models

Company Feedback

“Commendium approached the LPDU with the aim of devising a simple, accurate method of turning very large point cloud models of cave chambers into 3D models. Key was affordability. The team helped Commendium to select appropriate software and devise an appropriate and cost-effective method for measuring volumes and printing 3D models. They also provided independent verification of the veracity of the methods and calculations used. The team are very knowledgeable, capable, are highly articulate and great fun to work with.” Richard Walters, CEO, Commendium Ltd.

Researcher Feedback

“After data collection, several scale model sections of the cave were produced using a process referred to as Selective Laser Sintering. The models are helping the team at Commendium Ltd, and others with an interest, to understand more about the geology of these landforms. This demonstrates that 3D printing has a wide range of fascinating applications, and I was delighted to have worked on this project that has helped uncover the world’s biggest cave.” Jonathan Milburn, Graduate Engineer, Lancaster University.

Banner Image Copyright: © Carsten Peter/National Geographic - The photographer’s lights illuminate the green-hued Getu He river in the Miao Room— now considered the world’s largest cave chamber by volume. The Miao Room volume measurement exceeds Sarawak Chamber in Malaysia, the past title-holder, by about 10 percent. But the Malaysian cavern is still the world’s largest by surface area, with some 1.66 million square feet (154,500 square meters) of expanse.