Active Surfaces and Interfaces

We are working to understand and engineer how materials interact through their surfaces and interfaces.

Active surfaces and interfaces play an important role in many areas of materials science and engineering. Recognition of this as a thematic area provides solid foundations for international, national and local industry engagement. Underpinned by our core facilities, Materials Science helps nurture the philosophy and relationships required for competitive, larger grant applications.

The theme comprises four key, overlapping activities:

Modelling Surfaces and Interfaces

We have a comprehensive multiscale capability in modelling materials ranging from electronic and molecular structure, through the mesoscale, to large scale simulation.

We apply methods to study the structure, dynamics and properties of a wide range of surfaces and interfaces, with a central aim of integrating simulation alongside experimental measurement and the synthesis/manufacturing processes to constantly inform one another at all stages.

As well as standard modelling techniques (such as density functional theory, molecular dynamics and finite element analysis) unique specialisms to Materials Science include Quantum Monte Carlo, free energy calculations, quantum transport and ab initio modelling of actinides and lanthanides with relevance to the nuclear industry.

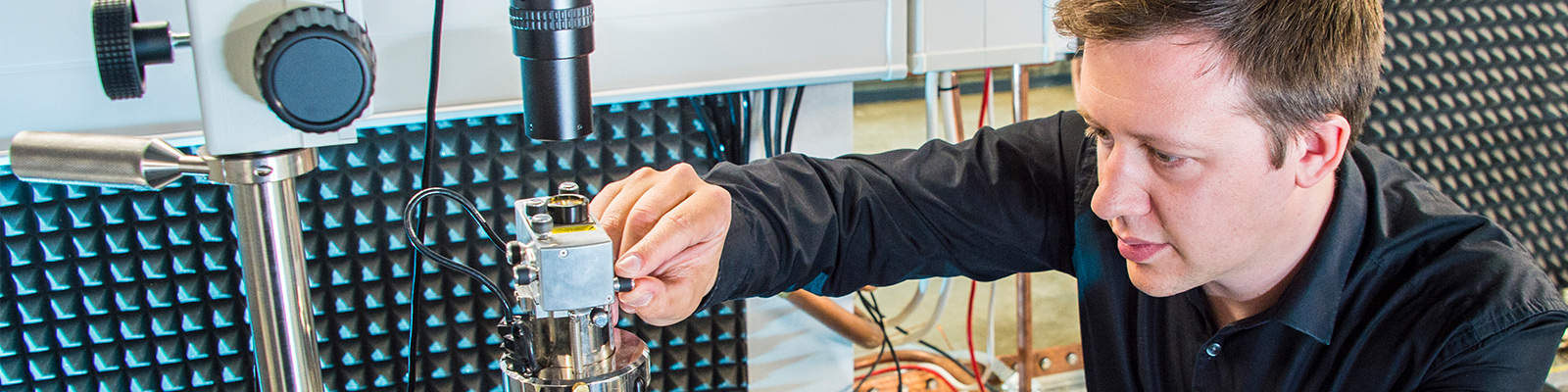

Measurement of Surfaces and Interfaces

Materials characterisation capabilities in Materials Science span length scales from single atoms to the mesoscale.

Our expertise and facilities enable us to work across a wide range of applications in surfaces and interfaces, including molecular coatings, CVD and MBE grown layered structures and devices, battery electrochemistry and electrocatalysis, 2D materials, energy materials, porous materials and biological interfaces and interactions.

Unique facilities at the centre include nanoscale resolution 3D mapping of internal structure (BEXP) of materials and buried interfaces, in situ NMR of disordered, amorphous and multiphase materials, nanometre scale mapping of thermal and mechanical properties, and atomic and single molecule resolution imaging.

Making of Surfaces and Interfaces

We manipulate materials at surfaces and interfaces over a large range of length scales from small organic molecules (nm) to composites for the building industry (metres). A recent expansion in synthetic chemistry and additive manufacturing has added significant capacity encompassing the range from the classical hard engineering materials to soft biomaterials.

Surface features and structured thin films can be engineered at Lancaster in-situ with sub-µm precision by using laser sintering, milling and machining. Energy- and material-efficient surface processing is achieved by multi-material additive manufacturing and carbon dioxide processing.

Molecular functionalisation of surfaces is achievable via two principal methods. Firstly, we carry out ex situ and in situ chemical synthesis, with the new chemistry transferred to substrates and/or devices. This mode of surface functionalisation is applied in applications spanning gas absorption, energy storage and generation, surface initiated “click-chemistry” and biologically-active molecular immobilisations. Secondly, we specialise in plasma polymerisation, a scalable gas-phase coating technique which allows industrial-scale processing across a broad range of materials to create nanoscale coatings for interfacial engineering. Applications of this approach range from high-performance fibre composites through to implantable biomaterials.

Applications

We take application and environment-driven approaches to the design of new surfaces and interfaces. Under laboratory testing conditions, performance is monitored and optimised via Lancaster’s world-leading modelling and measurement capabilities.

Moving to real-world applications, novel surfaces and coatings provide the versatile platform for building new materials and sensors for applications ranging from health technologies through to critical, demanding environments requiring self-monitoring, -healing and –adapting properties.