Application

-

Early diagnosis of asymptomatic disease

This actively leverages the discovery of new biomarkers for conditions such as non-communicable, degenerative diseases.

-

Early invention

For instance, cell therapies of chronic wounds or degenerative eye conditions.

-

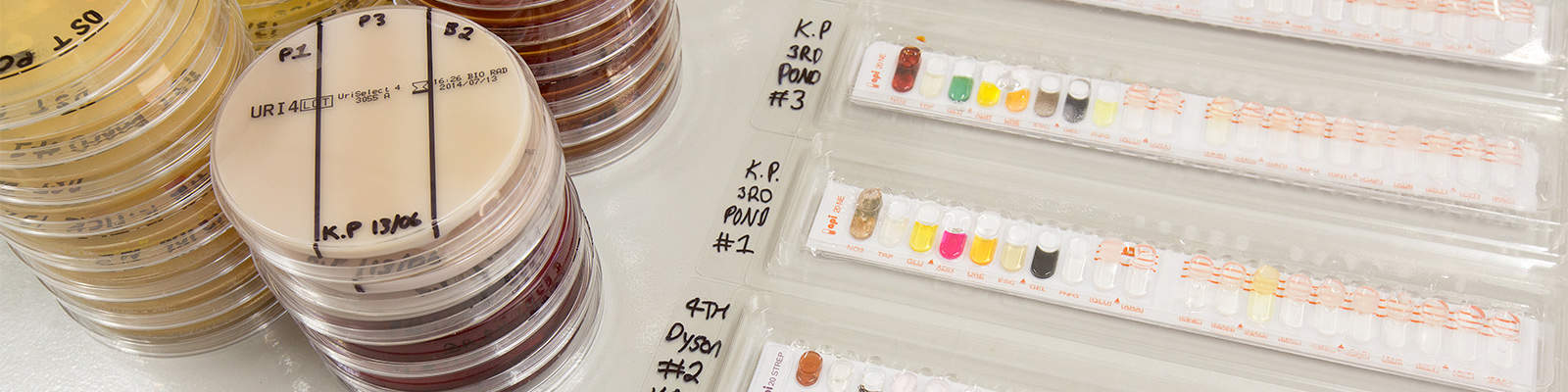

New approaches to fight the rise of antimicrobial resistance

Co-creating new research projects with Parasitology and Microbiology.

-

A better understanding of disease

Developing new research tools with the Cancer Biology and Genome Stability group within Biological Life Sciences.

Our Approach

Modelling Materials

In this strand of activity, using computational/theoretical modelling we can gain deep knowledge in the fundamentally understanding of the properties of materials and biological events. Our comprehensive multiscale capability in modelling materials ranges from electronic and molecular structure, through the mesoscale, to large-scale simulation.

We apply methods to study the structure, dynamics and properties of a wide range of materials (particularly surfaces and interfaces), with a central aim of integrating simulation in the iterative design loop.

In addition to standard modelling techniques (such as density functional theory, molecular dynamics and finite element analysis) unique specialisms to Materials Science Lancaster include Quantum Monte Carlo, free energy calculations, quantum transport and ab initio modelling of actinides and lanthanides with relevance to the medical imaging.

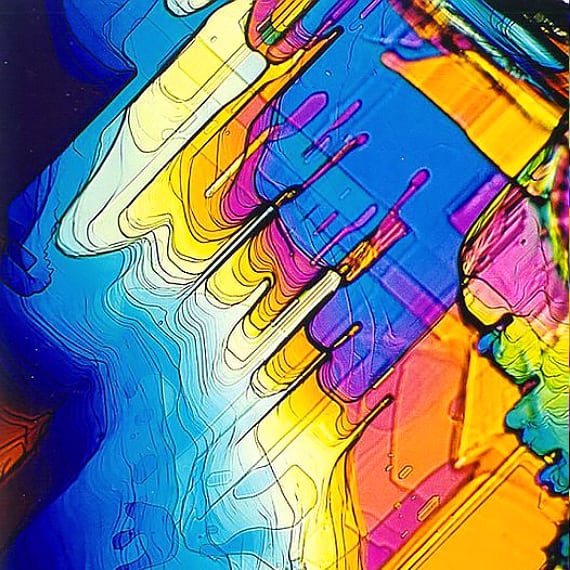

Measuring Materials

Materials characterisation capabilities at Materials Science Lancaster (MSL) span length scales from single atoms to the mesoscale. Our expertise and facilities enable us to characterise the materials that underpin healthcare technologies and their interactions with biological interfaces and, indeed processes within the biological interfaces themselves.

Measurement plays a key role in the design and optimisation of innovative materials for healthcare applications. State of the art facilities at the Centre include nanoscale resolution 3D mapping of internal structure (BEXP) of materials and buried interfaces, advanced analytical tools for nanoscale surface measurements (including state-of-the-art XPS), solid-state NMR of disordered, amorphous and multiphase materials, nanometre-scale mapping of electrical, mechanical and thermal properties, and atomic and single molecule resolution imaging.

We are developing micro-imaging Raman and FT-IR as methods for the early detection of asymptomatic disease.

Making Materials

We harness our expertise in chemistry, chemical engineering, chemical physics, engineering and biochemistry to synthesise molecules, materials and devices with interesting novel structures and properties. The structures of these are tailored to meet application-specific requirements. Iterative design strategies involve measuring the properties of materials, modelling (demonstrating our fundamental understanding of the properties of the molecules and their organisation in materials), and demonstrating their potential for various biomedically-relevant applications.

We have broad expertise in making organic, inorganic and hybrid materials, and a particular interest in the intermolecular interactions that underpin the properties of materials, and developing stimuli-responsive materials. Our state-of-the-art facilities enable us to make materials with a variety of biological, physicochemical, electrical, mechanical and topographical properties, tailored to the needs of specific healthcare technologies (e.g. biosensors, drug delivery systems, electrodes for neuromodulation, scaffolds for tissue engineering, theranostics.)

Plasma polymerisation is used to make ultra-thin film coatings for materials that can be used to bind biomolecules or cells to surfaces to enhance diagnostic technologies or for medical devices (early intervention).

Applying Materials

The aim of this strand is to accelerate new materials and/or devices into clinical testing.

Through phase 1-3 developments of the Health Innovation Campus, we will strengthen this capability, developing the capacity to serve both the north-west region and nationally.

Our aim to develop an absorptive capacity for translation and early-stage clinical trials.

Health Innovation Campus