About us

Molecular electronics uses individual molecules and molecular layers to perform functions, such as switching and memory, typically associated with traditional semiconductor devices. Our research has shown that the unique quantum and electronic properties of molecules has the potential to enable ultra-miniaturised devices surpassing current silicon-based technology in efficiency, scalability, and functionality.

Molecular electronics at Lancaster is an interdisciplinary research activity to develop novel molecular materials directed towards a range of applications with an emphasis on molecular electronics, green energy materials, digital chemistry, quantum electronic sensors, and novel molecular synthesis.

Our research is leading activity in organic thermoelectrics for waste heat recovery, low power memristive devices for neuromorphic computing and AI, small atom cluster ultra-efficient catalysts, amorphous porous materials for batteries and gas storage, quantum transport and on-chip atomic clocks, organic electronic materials, and organic synthesis and materials design.

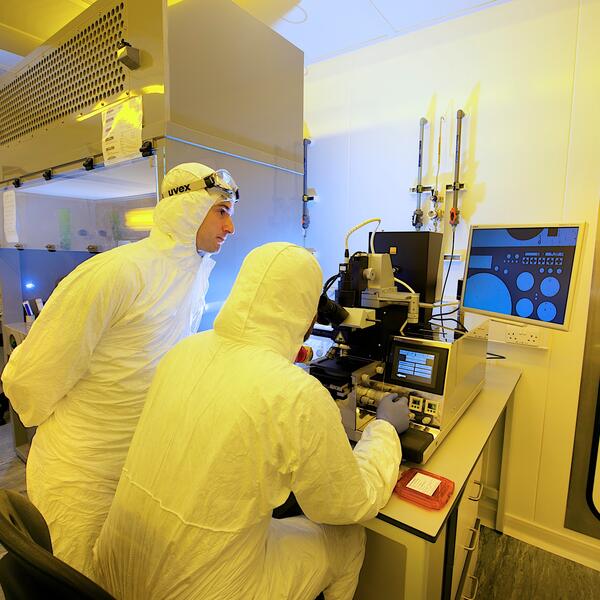

Molecular scale electronics at Lancaster is a major and rapidly growing cross-disciplinary theme, with £10M of grant awards in the last year and a working community of 7 senior academic researchers and over 40 PhD and postdoctoral researchers.

Recent Major Research Awards

Quantum engineering of energy-efficient molecular materials (QMol)

QMol is a £7M, five-year project, funded by the EPSRC. It is led by Professor Colin Lambert alongside Professor Benjamin Robinson and Dr Samuel Jarvis and a world leading team of scientists from Oxford University, University of Liverpool, Imperial College London, and the STFC Central Laser Facility, to develop radically new organic materials for everything from smart textiles to self-powered patches for healthcare.

QMol will realise a new generation of switchable organic/organometallic compounds, with the potential to fulfil societal needs for flexible energy harvesting materials, low-power neuromorphic computing, smart textiles and self-powered patches for healthcare. The possibility of creating these exciting materials derives from a series of world firsts by the investigators which demonstrate that advantageous room-temperature quantum interference effects can be scaled up from single molecules to self-assembled monolayers by using new strategies for controlling molecular conformation and energy levels with new methods of molecular assembly which can then be deployed in printed scalable architectures.

For more details see the QMol website.

Memristive Organometallic Devices formed from self-assembled multilayers (MemOD)

MemOD is a £2.1M EPSRC Project led by Professor Benjamin Robinson in collaboration with Professor Colin Lambert at Lancaster, Professor Christopher Ford of the Cavendish Laboratory, University of Cambridge and Professor Martin Bryce of the Department of Chemistry, University of Durham.

The aim of the MemOD project is to demonstrate a new class of high-performance memristive devices formed from ordered, self-assembled molecular multilayers of novel organometallic components, in contact with scalable, CMOS-compatible electrodes. Our vision is to make the next step change towards new technologies for faster, more powerful and more energy-efficient computing architectures.

Vibrating carbon nanotubes for probing quantum systems at the mesoscale (Mesophone)

Mesophone is a six-year €2.7M project funded by the ERC and led by professor Edward Laird to explore mesoscopic quantum effects using carbon nanotubes. The mesoscopic scale spans the boundary between the macroscopic and microscopic realms, where classical and quantum physics hold sway, respectively. Many fascinating quantum phenomena can emerge at the mesoscopic scale. The EU-funded MesoPhone project will use vibrating carbon nanotubes to probe quantum phenomena at the mesoscopic scale. Nanotubes are ideal for experimental investigations in this region as they can be isolated from thermal noise and be deflected by tiny forces. Moreover, because of their small size, their behaviour is significantly affected by quantum jitter. The project's results could help resolve longstanding questions in physics, such as whether a moving object that contains millions of particles could exist in a superposition of states.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)