The Challenge

The hospital environment can be extremely chaotic. However, it is of the utmost importance that patients, particularly in critical care and other high dependency wards, experience good quality sleep. Royal Preston Hospital was researching how adequate rest on the ward affects patient recovery. Their staff measured ambient noise in decibels with a traffic light system used to indicate high levels (bad) and low levels (good). Collating this data over several points of 24 hours to identify patterns.

They demonstrated that reductions in noise levels could improve sleep and reduce the incidence of delirium and therefore, the overall length of stay of patients. Devices that give traffic light indications for noise levels and other parameters already exist, prompting ward staff to change behaviours. Royal Preston Hospital wanted a similar system that warns when light levels are too high when patients are trying to rest. This system could help contribute to quality sleep and therefore, to recovery.

The Solution

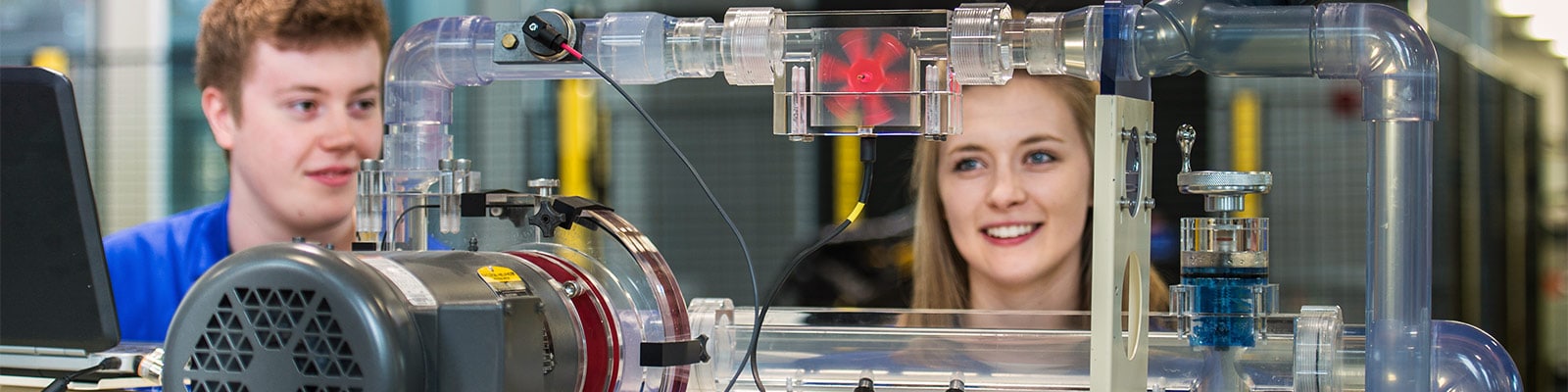

A team of four third-year MEng Engineering students developed a potential solution in just over two weeks. They started by developing a product specification with hospital staff, outlining and agreeing on objectives. The group then conducted assessments of the different technologies, reviewing criteria such as cost, sensitivity, durability, and integration into the ward environment.

They undertook mind-mapping exercises and then developed system concepts illustrating their ideas and shared them with NHS staff to gather feedback. Following this, they developed the prototype, including designs for software and hardware, and tested it at the University. Based on feedback and testing, they produced a final system which included housing, electronics and fully-configurable software.