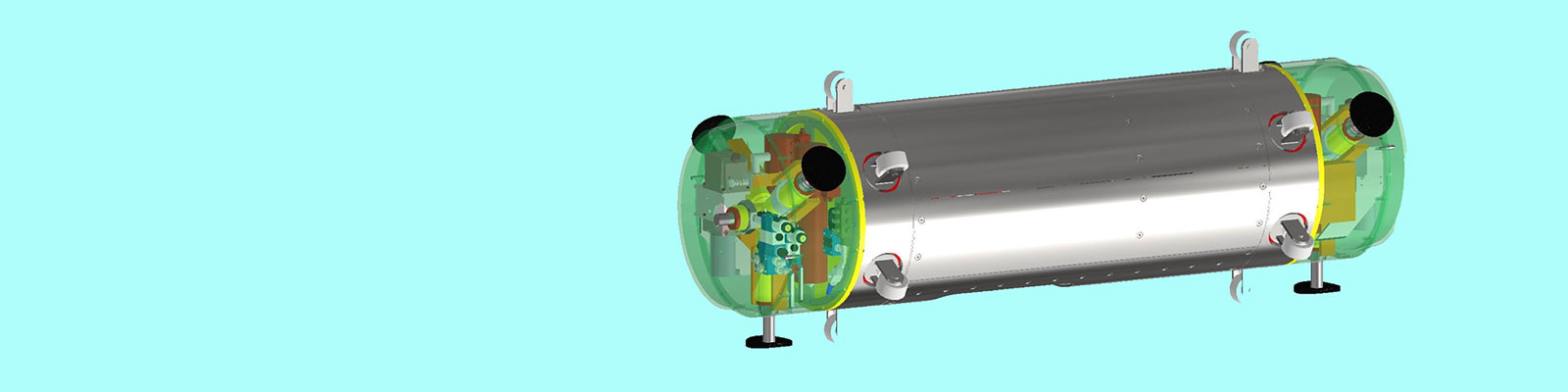

FSWBot aims to create a robotic system, integrating several technologies including friction stir welding (FSW), ultrasonic non-destructive testing (NDT), milling and patch deployment, that can be deployed to conduct repairs on subsea pipelines while they are operational. The FSWBot comprises four articulated carriages: a power generation carriage, two carriages for battery storage and one for the control system.

The plan is for the FSWBot to be able to enter a pipe segment that contains defects previously mapped out using a magnetic flux leakage (MFL) survey; correctly position itself to perform the repair on the first defect; machine away from the corroded area and produce a pocket in the pipe wall into which a steel patch will be placed; weld the patch into place; and use the milling tool to ensure the weld is flush with the pipe wall. The machine will then use NDT to inspect the weld, after which it will unclamp and move downstream to repeat the process on any further defects. The data generated, such as location, and pre- and post-weld ultrasonic scan data, will be stored for later use in order to increase the level of autonomy using artificial intelligence (AI and machine learning).

Once the prototype FSW system is ready for testing, the project partners will seek to demonstrate that a patch weld can be carried out in-situ, for example, to rectify a corrosion induced defect, on a 36 inch (91cm) diameter, oil-filled, steel export pipe.

Project partners: Forth Engineering, Innvotek, London South Bank University, TWI and Joining 4.0 Innovation centre (J4IC – a strategic partnership between Lancaster University and TWI).

This project was funded by Innovate UK.